Produce superior quality hay with HAYTECH

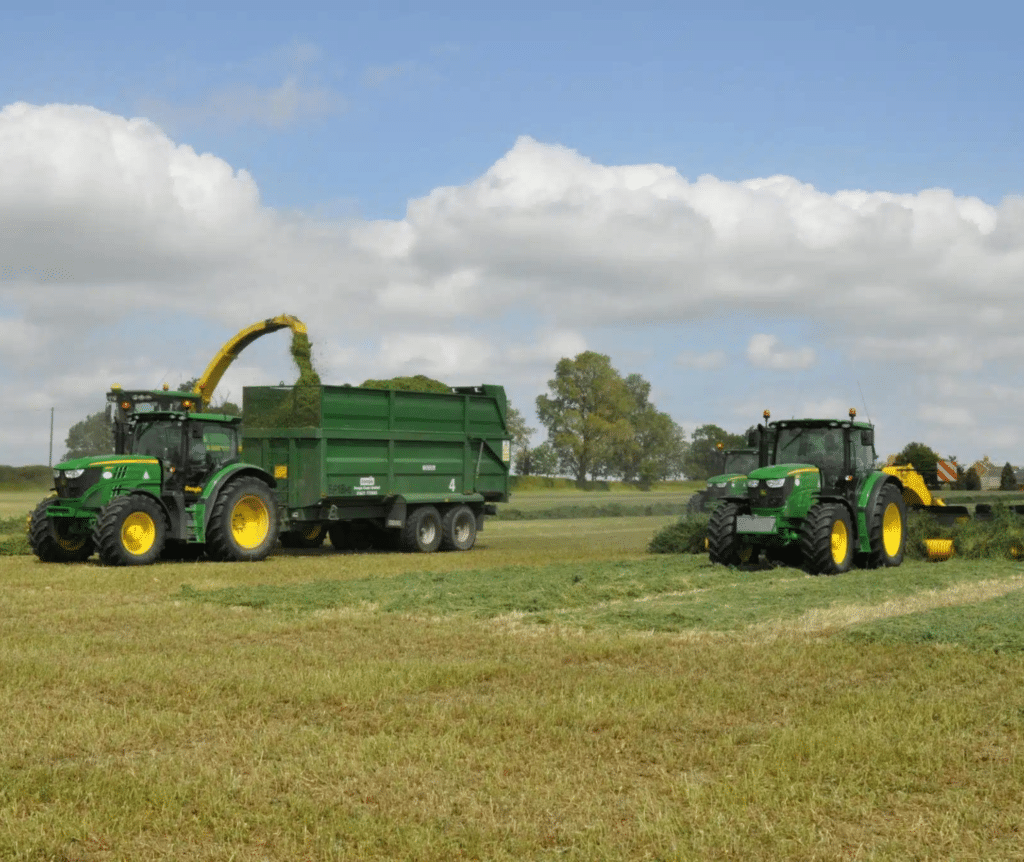

Situation

Production managed from A to Z

The farm specializes in the production of high-quality hay for small animals. Each year, they produce about 800 square bales of 80x60x200.

They take care of every step of the production: from soil preparation to harvesting, drying, transporting and packing the hay. The processes as well as the final product are constantly monitored and controlled by biologists and external service providers.

In 2023, they plan to expand to about 220 hectares and to add a bulk hay dryer.

Finding a solution to monitor the hay during drying and avoid fire hazards was necessary.

Solution

Protecting hay during storage

Hay moisture and harvest time change from year to year, and fermentation is inevitable with fresh hay. By managing all stages of hay production themselves, they are aware of the importance of monitoring the temperature of hay bales during storage.

Spontaneous combustion is an unpredictable consequence, even for experts. The more bales of hay stored and the higher the pile, the higher the risk of fires.

HAYTECH allows them to continuously monitor the temperature of each bale of hay in real-time and without any worries. This allowed them to eliminate the need to measure temperatures with a manual probe, minimizing the risk of the hay heating up.

- Better monitoring of real-time temperatures of their hay

- Increased monitoring of hay bale count

- Continuous data

Impact

High-quality, safe hay

With HAYTECH, they can continuously and easily check the temperature inside the hay bales and receive important data in real time directly to their phone.

HAYTECH facilitates and professionalizes all their hay production processes by eliminating manual measurement and minimizing the risk of hay heating. The farm avoids any risk of fire and provides SMS alerts in the event of high temperatures allowing them to react in time.

The HAYTECH system also allows them to ensure the quality of their hay thanks to the ultra-precise data provided by the probes on each bale of hay.

- Constant monitoring of their production

- SMS alerts in case of overheating of hay

- Monitoring the quality of the hay on the application

HAYTECH invited itself into their home.

Discover how Haytech has improved hay management!